Grease separator - ACO Germany

Grease separator is an indispensable device to treat waste water containing grease in the food processing process in every kitchen of a restaurant, hotel, cafeteria, industrial processing facility or industrial area. apartment,…

Featured Product: Grease separator - ACO Germany

Category grease separator - aco germany

APPLICATION FOR GREASE SEPARATOR

ACO provides grease separator systems as a complete solution for a range of projects such as hotel, hospital, shopping mall,…

Grease separators are used wherever animal or vegetable fats are carried into waste water. They need to be adapt-able and versatile, and be available in various sizes and materials to meet the enormous range of different industrial and commercial needs

THE BENEFITS OF GREASE SEPARATOR

ACO offers a comprehensive range of step increases in nominal sizes for dimensioning grease separators, both those for free-standing installation and those for below ground installation. This means the perfect solution can be provided according to the level of waste water to be dealt with; there is no need to take the next highest nominal size for reasons of capacity, which saves money and space.

In order to reduce microbes, hot water is used for rinsing in hospitals, catering facilities and homes for senior citizens in particular, with the separator logically being exposed to that same water. The same things are applied to the emptying of tilting frying pans and boilers.

Furthermore, irrespective of the material, a large selection of extension stages are available, each of which can increase operational and cleaning safety. This is achieved by additional components such as systems for inner cleaning, as well as filling devices and disposal pumps. Measuring devices are also able to monitor operating conditions and reliably forward them to corresponding monitoring devices.

Safety

-

Plan with certainty, thanks to a huge choice of materials

-

Solutions for all types of construction

-

No additional fire load introduced to the building thanks to the use of stainless steel (building material class A1)

Hygiene

-

Plants available in stainless steel

-

Effective inner cleaning to remove all residue in the separator

-

Homogenising and cleaning in a single step

-

Hydro-mechanic high-pressure inner cleaning (150 bar, 360°)

-

Neutralization of odours

-

Cover can remain closed during inner cleaning

Profitability

-

Disposal to meet your requirements by measuring the grease layer

-

Fast troubleshooting, thanks to GSM module

-

One module for all ACO products

-

Avoidance of the heavy polluter surcharge

-

Odour neutralizer for a grease separator (basic model, extension stage 1)

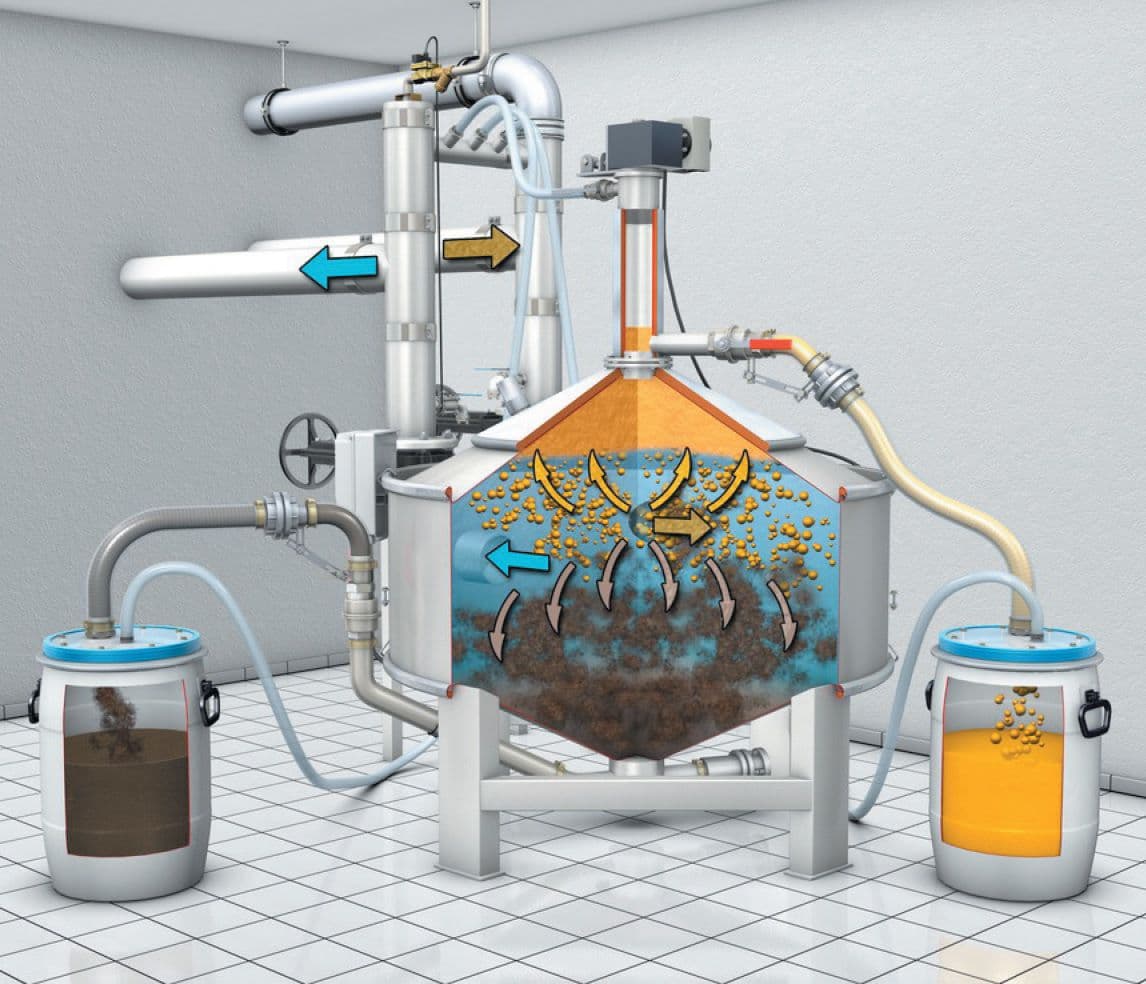

PRINCIPLES AND FUNCTION

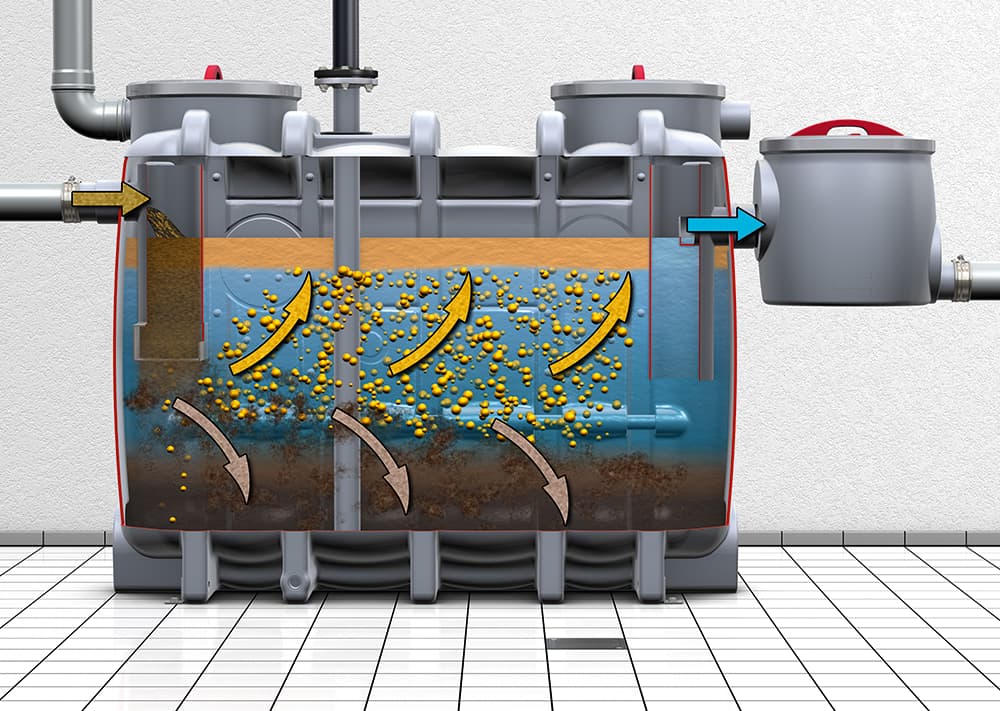

A grease separator works purely physically, applying gravity (difference in density). For example, heavy waste water contents sink to the bottom and light substances such as animal oils and fats rise to the top of the separator. The grease layer can be broken down in a targeted manner using the high-pressure jet of up to 150 bar from the special rotating cleaning head and homogenised, so it is ready to destroy. Depending on the location situation, the contents of the separator can be sucked out by the disposal vehicle via permanently installed local piping or conveyed too using an optional disposal pump.

There are different kinds of grease separators with different operating principle:

Operating principle for full disposal/free-standing installation

Grease separator for full disposal

With grease separators for full disposal, sludge and grease are collected in the separator container installed in the building and picked up by a disposal contractor at certain intervals or as required

Operating principle for full disposal/below ground installation

With grease separators for full disposal and below ground installation, sludge and grease are also collected in the separator container and picked up by a disposal contractor at certain intervals or as required. The grease separator takes up less space of the outdoor surface and can be emptied in a way that minimizes odours via direct suction equipment installed in the soil.

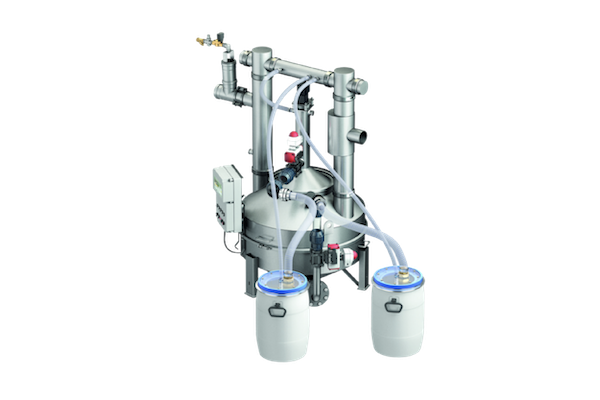

Operating principle for partial disposal

Grease separator for partial disposal

With grease separators for partial disposal, sludge and grease are collected in separate containers. This can be done manually or automatically via an additional control.

Buying grease separator at COMBITEK VIETNAM

Currently on the market, there are a number of brands that provide grease separators products, but for the best advice and support as well as choosing to buy standard quality products, the address where you should "choose" is VIET NAM COMBITEK TECHNOLOGY JOINT STOCK COMPANY.

As a leader in the market of providing central hot water system, grease separators solutions with over 10 years of operation and development, Combitek has successfully implemented many large projects such as the Government Office, the National Assembly Building, luxury apartments and hotels across the country.

Besides, a team of professional and enthusiastic technicians who are always willing to answer and support all requests at any time is something that customers trust and love Combitek during the past time.

With the completed and detailed information about the grease separator mentioned above, surely you will no longer have to worry about grease in cooking as well as in daily life.

VIET NAM COMBITEK TECHNOLOGY JOINT STOCK COMPANY

Hotline: 024 3212 7028

Website: https://www.combitek.com/

Address: Tầng 6, Tòa nhà Sông Hồng, Số 2, Trần Hưng Đạo, Hoàn Kiếm, Hà Nội

Email: info@combitek.com; combitekvn@gmail.com